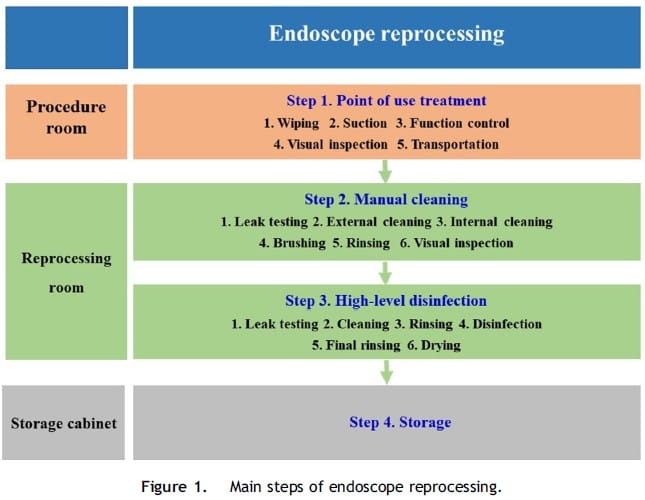

Endoscope Reprocessing & Handling:

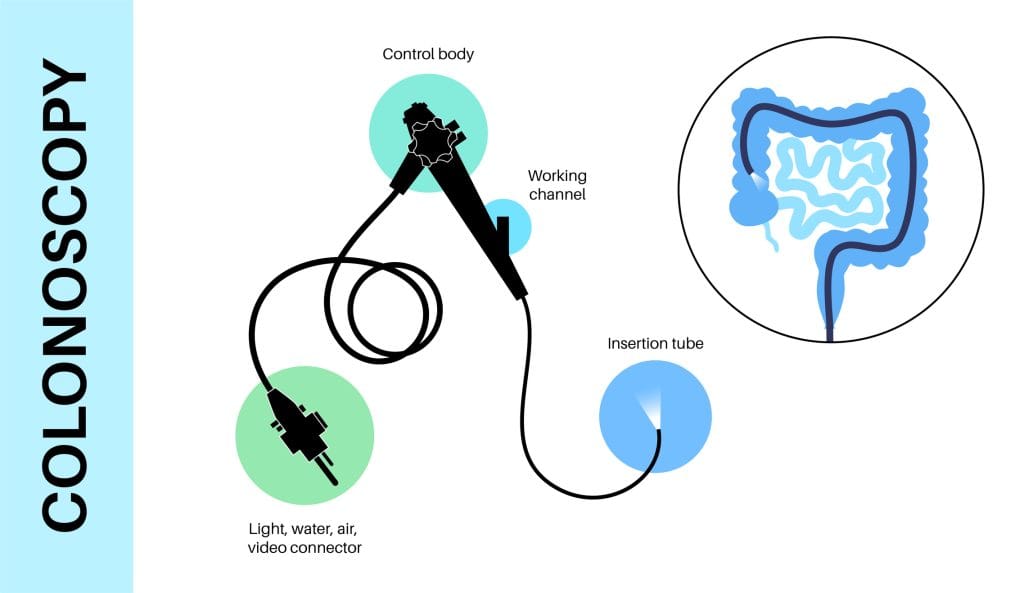

Endoscope Reprocessing is a multi-step, highly complex activity which includes pre-cleaning, leak testing, manual cleaning, rinsing after cleaning, visual inspection, high level disinfection (HLD), rinse after HLD, drying, storage and documentation.

Endoscope is usually reprocess in the Endoscope Washer Disinfector (EWD)

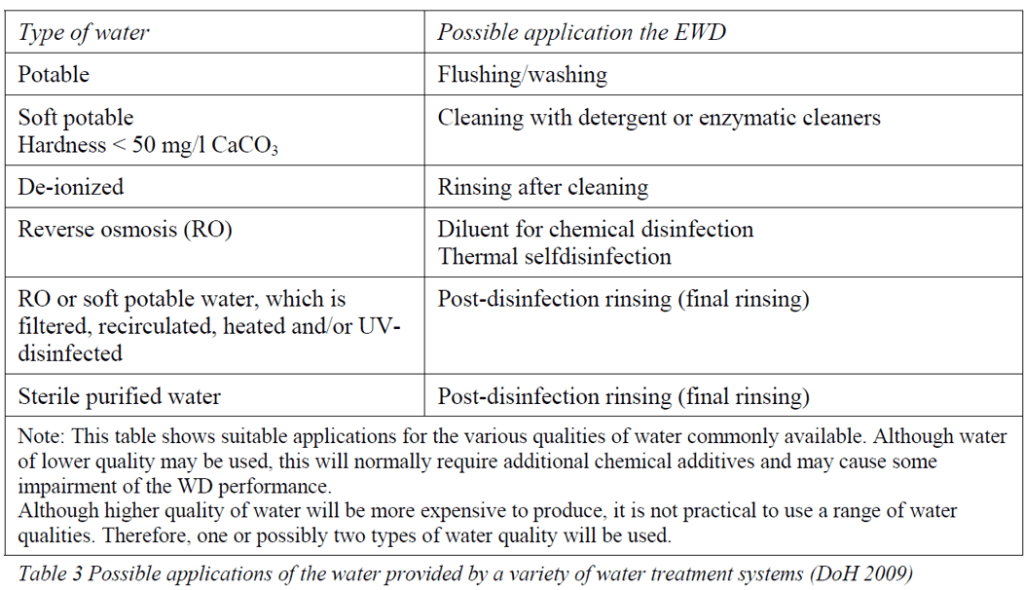

Water is used in the Endoscopy Unit for Endoscope Reprocessing:

a) Initial rinse-water;

b) Intermediate rinse-water

(not a critical factor if disinfectant and cleaning agents are compatible);

c) Final rinse-water

d) Diluent for chemicals.

Water Hardness

Water hardness Hard water (>200 mg/L CaCO3 equivalent) used in final rinse in the AER cycle may cause deposits on the endoscope.

- These deposits will act as potential focus for soiling and recontamination of the endoscope.

- It may also seriously impair the optical system of the endoscope.

Temperature

- Endoscopes are unable to tolerate temperatures of 60°C or above, they cannot therefore be thermally disinfected and sterilised.

- Instead, endoscopes are cleaned and sterilised using a chemical disinfection procedure and then rinsed in purified water (Final rinse water) to remove all traces of the disinfectant.

- Water at too high temperature during the initial flushing stage may lead to the coagulation of proteins and may “fix” proteinaceous soil to the surface in parts of the endoscope.

- Refer to manufacturer’s Instruction for Use (IFU) on optimal temperature setting required for the detergent and disinfectant used.

Microbial contamination

- Water supply to AER should be treated using filtration, deionisation, or reverse osmosis (RO).

- A 0.2µm filter is adequate to remove common microbial pathogens.

- Deionised water may become contaminated with microorganisms and the resin column colonised with bacteria; hence it should be further decontaminated (i.e. either by heating or filtration etc) if used for final rinse of products intended for invasive use.

- RO is performed under pressure through a semi-permeable membrane against an osmotic gradient.

- The process will also remove a high proportion of organic material, bacterial endotoxins, and microorganisms.

- RO units are fitted with a final endotoxin filter to control bacterial numbers are recommended.

Use of Water Softeners

Water softeners, or base-exchange softeners, consist of an ion-exchange column containing a strong cation resin in the form of Sodium Chloride.

Calcium and magnesium ions in the water are replaced by sodium ions.

The remaining sodium salts do not, like calcium salts, form hard deposits to foul heat exchangers or spray nozzles.

But if used as the final rinse they will leave white deposits on the load items as they dry.

The process is simple to operate with an automated in-line system, it will handle water with varying levels of hardness, and is simple and safe to regenerate.

The down sides are that after regeneration high levels of chloride ions might be present in the initial output from the softener, which should be run to waste.

Base-exchange softeners can cause a significant increase in the microbial content of the water, which should be taken into account when establishing the operational parameters of the microbial water treatment systems.

Recommendations:

- Regular microbiological sampling of the rinse water is required to determine the risk References for Pseudomonas aeruginosa and atypical Mycobacterium species contamination.

- Water used for cleaning and disinfection should be treated using filtration, reverse osmosis (RO) & deionization,

- An endotoxin filter is required to remove common microbial pathogens at the downstream of the system.

References:

THE NATIONAL INFECTION PREVENTION & CONTROL GUIDELINES FOR ENDOSCOPY CENTRES 2023 (MOH)

Quality of the final rinse water for endoscope washer disinfectors A literature review

Adrie de Bruijn, Arjan van Drongelen

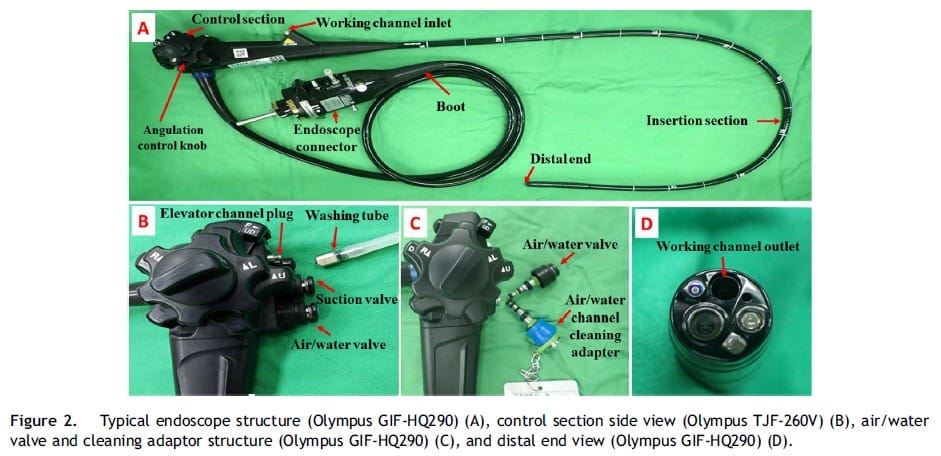

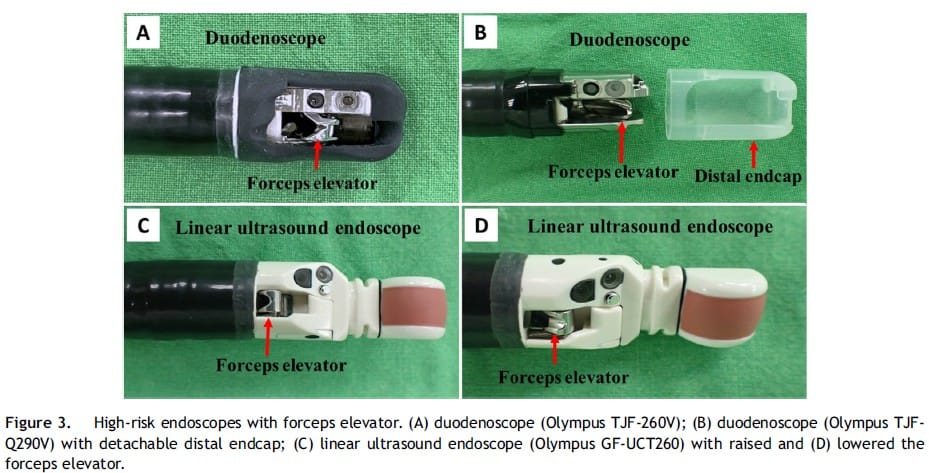

Recommendations and guidelines for endoscope reprocessing: Current position statement of digestive endoscopic society of Taiwan

Illustrations from: https://www.istockphoto.com/

Ready to Transform Your Water?

If you’re looking to elevate your facility’s water standards, you’ve come to the right place. Let us help you achieve industry compliance while enhancing operational efficiency. Simply fill out our contact form, and one of our specialists will guide you through the process of transforming your water quality.