Different Types of Steam Generation

Pure Steam – Pharmaceuticals and biotechnology; injectable drug production. Uses water for injection (WFI).

Clean Steam – Healthcare facilities, laboratories, food & beverage. Uses RO/DI water.

Plant Steam – Healthcare facilities, laundries, food & beverage, pulp & paper, petrochemical.

Uses softened/treated potable water.

How does Water Quality affect Steam Sterilization?

Water known as “the universal solvent” due to its ability dissolve more ions and substances compared to any other solution.

Often tap water is found to contain impurities, trace minerals and other contaminants such as metals, salts, and organic molecules derived from the environment or the water delivery system.

ELEMENTS OF CONCERN IN POTABLE WATER | EFFECT ON INSTRUMENTATION | WATER TREATMENT OPTIONS |

Presence of metals (Aluminium, copper, iron, rust etc.) | Instrument staining, chamber discoloration Harbour bacterial growth | Addition of inline filters and reverse osmosis (RO) treatment system |

Hardness (presence of calcium and magnesium) | Scale formation from mineral deposits | Addition of softeners in feed water |

pH / alkalinity (presence of carbonate, hydroxide, and bicarbonate) | Instrument pitting, staining, and corrosion | Chemical dosing |

What is Critical Water ?

- Membrane separation process for purifying water.

- Water is de-ionized.

- Purifies water by removing containments, salts and other impurities.

Advantages: Removes dissolved inorganic solutes, bacteria and bacterial endotoxins

Safe to use for final rinse and steam generation

What is Softened Water ?

Calcium, magnesium is removed.

Advantages: Prevents scale built up and deposits.

What is Facility/Utility Water ?

Advantages: For initial flushing, washing, rinsing instruments

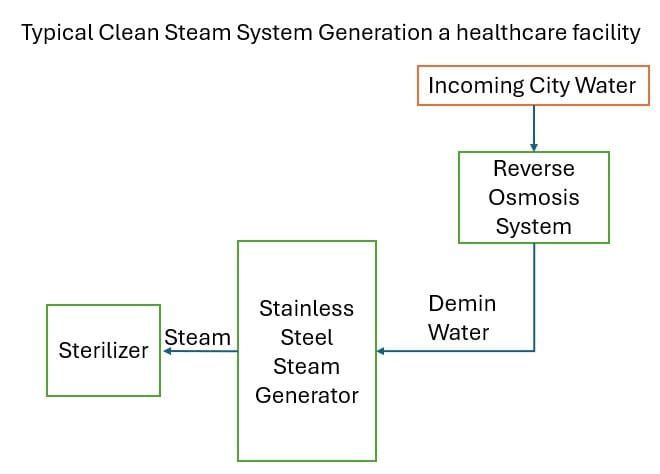

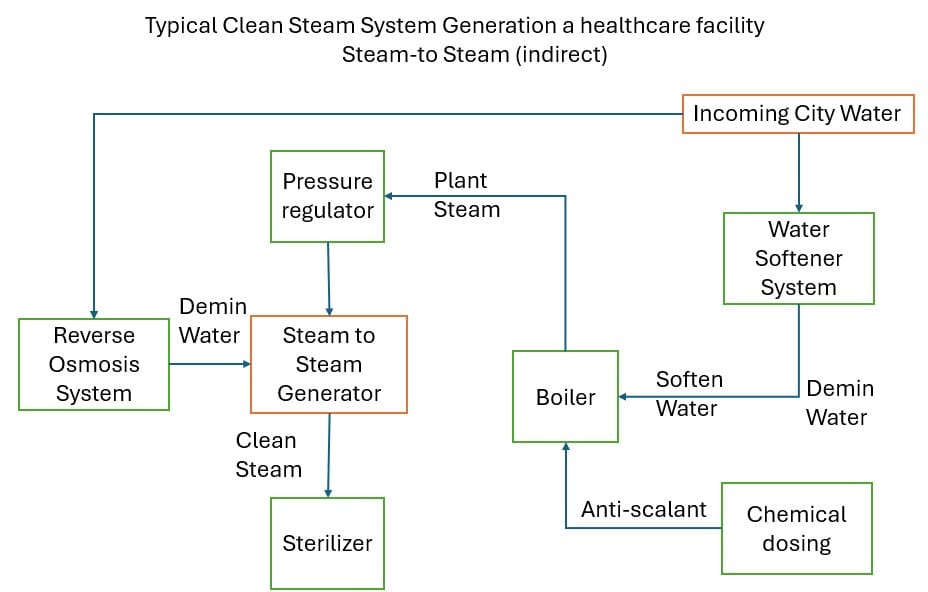

How is Clean Steam Made?

Electric heating elements can power clean steam generators, or they can use house steam to heat RO/DI water in a heat exchanger indirectly via heat exchangers.

This type of generator is also known as a steam-to-steam generator.

This process ensures the generated steam is free from additives and impurities that could compromise sterility.

Electric clean steam generators can be integrated within the sterilizer framework to minimize footprint requirements or be standalone generators.

Ready to Transform Your Water?

If you’re looking to elevate your facility’s water standards, you’ve come to the right place.

To protect the sensitive medical devices that require frequent cleaning and sterilization, hospitals must install water treatment systems designed to treat municipal water supplied to the sterile processing systems (e.g., steam sterilizers, ultrasonic cleaners, washers, sinks etc.)

Let us help you achieve industry compliance while enhancing operational efficiency.

Simply fill out our contact form, and one of our specialists will guide you through the process of transforming your water quality.